Recognised as one of Australia’s leading advanced manufacturing service providers. We deliver integrated, end-to-end solutions offering a true one-stop-shop for design, engineering, precision manufacturing, and project execution.

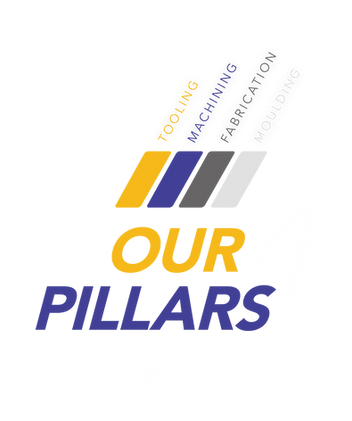

OUR 4 PILLAR SERVICE

At PRECISE MFG, we have earned our reputation by consistently delivering high-quality machining, manufacturing, and tooling solutions, on time and to exact specification. From complex, small-scale components to large-format production, our results speak for themselves.

Our four pillars stand for more than our core services but also a tribute to our founder’s German high-performance engineering heritage. defining the essence of our brand, and paying homage to our founder Manfred Tinney, a master toolmaker in German high-performance engineering.

These aren’t just our services; they’re a living tribute to Manfred’s legacy. Rooted in German high-performance engineering, our logo is a symbol of where we come from and where we’re going, a nod to the DNA that shaped our story.

TOOLING

We offer high-quality tooling for our plastic injection moulds either in-house at our Australian facility or through our trusted vendor network. Both options are managed to the same exact standards, ensuring precision, consistency, and reliable lead times. Whether produced internally or externally, all tooling is overseen by our team to maintain full quality control and seamless project delivery.

MACHINING

Our machining capability delivers tight tolerances, complex

geometries, and consistent quality. We offer precision CNC machining with multiple in-house CNC machines, with up to 1.6 meter machining capability, offering a wide range of material, including titanium, alloys, and carbon-fibre, ensuring versatility in all your projects. From prototypes to production runs, we machine with precision.

FABRICATION

Our fabrication capabilities combine skilled craftsmanship and modern technology to produce high-quality assemblies and components. Equipped with two state-of-the-art laser cutters featuring 3D laser capability, and

advanced CNC Brakes for superior metal forming, we leverage cutting-edge technology to meet the most demanding fabrication requirements.

PLASTIC INJECTION MOULDING

Explore our modern facilities

in Adelaide & Melbourne,

Australia and Troy, Michigan,

U.S.A. Offering services including contract assembly and drilling / machining. Our plastic injection moulding machines range from 25 to 1100 tons, producing high-performance plastic components across a wide range of industries, from concept to completion.

OUR MISSION

Quality Manufacturing.

On-time Solutions.

Our mission is to deliver innovative, high-quality products and exceptional customer service that consistently exceed our clients’ expectations, fostering long-term relationships built on trust and satisfaction.

Get in contact and ask for a quote today.

OUR VISION

Build Smarter.

Manufacture Faster.

Partner Better.

Our vision is to become a leader in end-to-end advanced manufacturing services offering a one-stop-shop for design, engineering, precision manufacturing, and project execution. Assisting companies in all different industries to unlock production of high complexity, high performance, robust and reliable components.

To continuously exceed our customers’ expectations in quality turn-key solutions, flexible lead times and end-to-end manufacturing process. Managing a diverse and profitable business, operating in Australia with a reputation for innovation, quality and delivery on time.

WHY PRECISE MFG?

Innovation:

We’re consistently moving forward and innovating new ways to streamline processes and timeframes to meet your deadlines. Focus on low maintenance tool designs reducing manhours after tool production.

Technology:

We use the most up to date technology and computer assisted software to provide the best results for our customers.

Cost:

Cost engineering process from start. Comprehensive design and build consultation process.

Strong relationships with partners from LCC.

Precise:

Our experience and expertise ensure we always provide the right advice and the right costs, be it for moulds or parts.

Global reach:

Global customers since it’s inception, Starke-AMG has worked with customers and partners worldwide.

Long standing manufacturing partners.

Experience:

35 years' experience in international tooling. Expertise in complex and large moulding tools.

Location:

Offices in Australia & USA. We have the flexibility to meet with customers in person or online.

Customer assistance:

Assistance from project KO to DFM to tool build to trials. Our team supports on-site and simplifies communication resulting in reduction of customer personnel required on projects.